Custom injector molding is a production process that plays a crucial role in the fabrication of various plastic parts and products. This methodology involves the use of a specially designed mold where molten plastic substance is injected under stress. As the plastic cools, it hardens into the form of the mold, allowing for the creation of intricate forms that would be challenging or expensive to obtain through other production techniques.

One of the key advantages of custom injector molding is its ability to produce large volumes of uniform components with precision and consistency. This makes it an optimal choice for industries ranging from vehicle to consumer goods. Understanding the basics of custom injection molding not only helps manufacturers optimize their production processes but also allows businesses to create tailored solutions that meet particular needs and specifications. Whether you are aiming to produce samples or high-volume products, tailored injector forming offers adaptability and efficiency that can greatly benefit your processes.

What is Tailored Injection Molding?

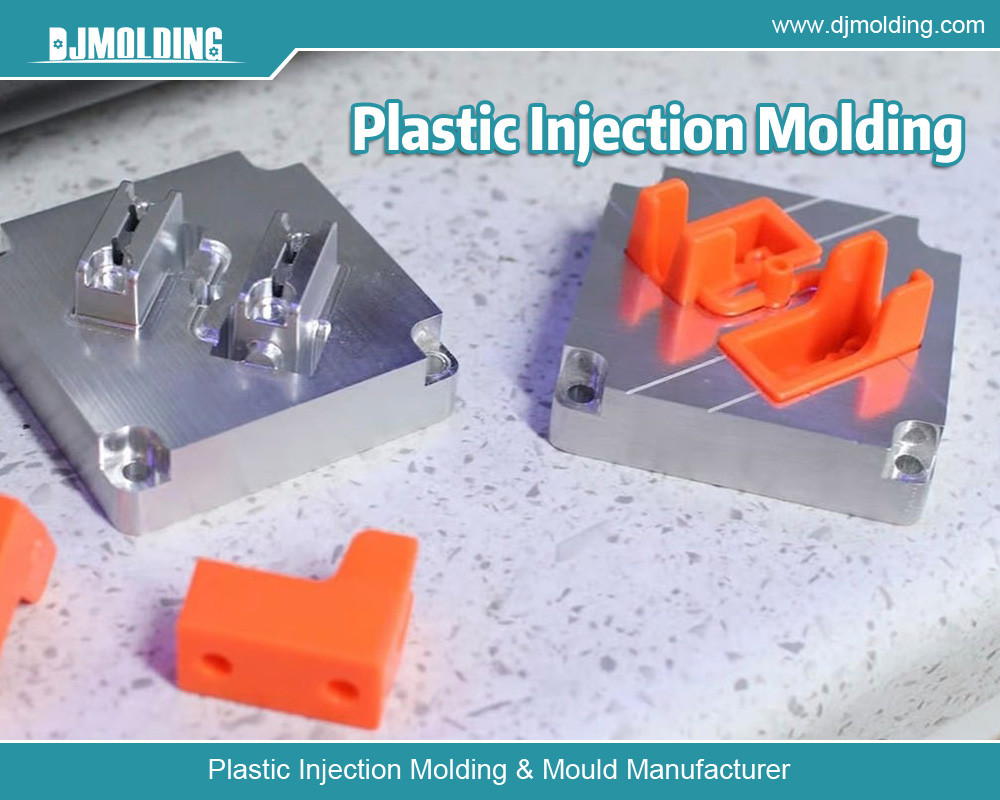

Tailored injection molding represents a manufacturing process used to produce parts by forcing molten material into a pre-designed mold. Such a technique enables the creation of intricate designs and forms that would be challenging or not feasible to create with other manufacturing methods. Mainly applied for making plastic parts, personalized injection molding can accommodate a wide variety of materials, including various thermoplastics and thermosetting plastics.

The process begins with the production of a casting, which is commonly made from metal or aluminum. This mold is engineered to the precise specifications of the desired part, ensuring precision and uniformity. Once the mold is prepared, plastic pellets are heated until they liquefy and are subsequently injected into the mold cavity. After the material solidifies and solidifies, the mold is opened, and the final part is released. This method allows for elevated production rates and can be economical for large volume runs.

One of the major benefits of custom injection molding is its ability to produce complex geometries with a high degree of accuracy. Additionally, the process offers versatility in terms of material selection and color options. Companies can utilize personalized injection molding to create customized solutions that meet particular industry standards, making it a favored choice for industries ranging from car manufacturing to consumer goods.

Benefits of Custom Injection Molding

Tailored injection-molding provides an variety of advantages that make it a popular manufacturing process for multiple fields. One of the key advantages is the capability to manufacture sophisticated geometries with great precision. This method allows for intricate patterns that may be hard or unfeasible to obtain through alternative fabrication techniques. With cutting-edge mold patterns and machinery, manufacturers can build elements that tightly align with the specifications provided, which leads to improved fit and function.

Additionally important benefit is the efficiency of the custom injection molding process. Once the forms are produced, producing large quantities of parts becomes a efficient and cost-effective process. This effectiveness not only enables for speedy manufacturing but also decreases the overall cost per unit as production volumes increase. Additionally, the automated processes involved in this process reduces labor costs and boosts uniformity in the standard of the final products.

In addition, custom injection molding accommodates a wide range of substances, including plastics and composite materials, which can be tailored to meet specific performance requirements. This flexibility enables companies to select materials that most suit their applications, whether they need enhanced strength, durability, or aesthetic qualities. As a result, businesses can develop novel products that meet market demands while also optimizing their production processes.

Applications of Custom Injection Molding

Tailored injectable molding is broadly applied across diverse industries due to its versatility and effectiveness. A of the most significant notable applications is in the automotive sector, where producers rely on this method to produce a variety of parts, including instrument clusters, housings, and other intricate parts. The ability to develop sophisticated shapes and geometries with precision makes custom injection molding essential for attaining both functionality and visual appeal in automotive design.

Another important application is present in consumer products. Goods like packaging, kitchenware, and toys often rely on custom injection molding for their production. The method allows businesses to meet custom design specifications while upholding affordability in mass production. Additionally, the extensive variety of materials available for injection molding permits manufacturers to pick the best options for longevity and efficiency based on the intended use of the goods.

Medical devices and equipment are also major beneficiaries of custom injection molding . The ability to manufacture accurate, clean, and top-tier medical components is critical in this industry. Custom injection molding allows for the development of sophisticated shapes necessary for devices such as syringes, surgical instruments, and various diagnostic tools. This method not only ensures adherence with rigorous regulatory standards but also supports advancement in the development of new medical technologies.